Methane Digesters

Methane digesters are technologies that convert organic waste into methane gas, which can be used to generate electricity. This process has the potential to reduce greenhouse gas emissions by capturing methane that would otherwise contribute to atmospheric warming.

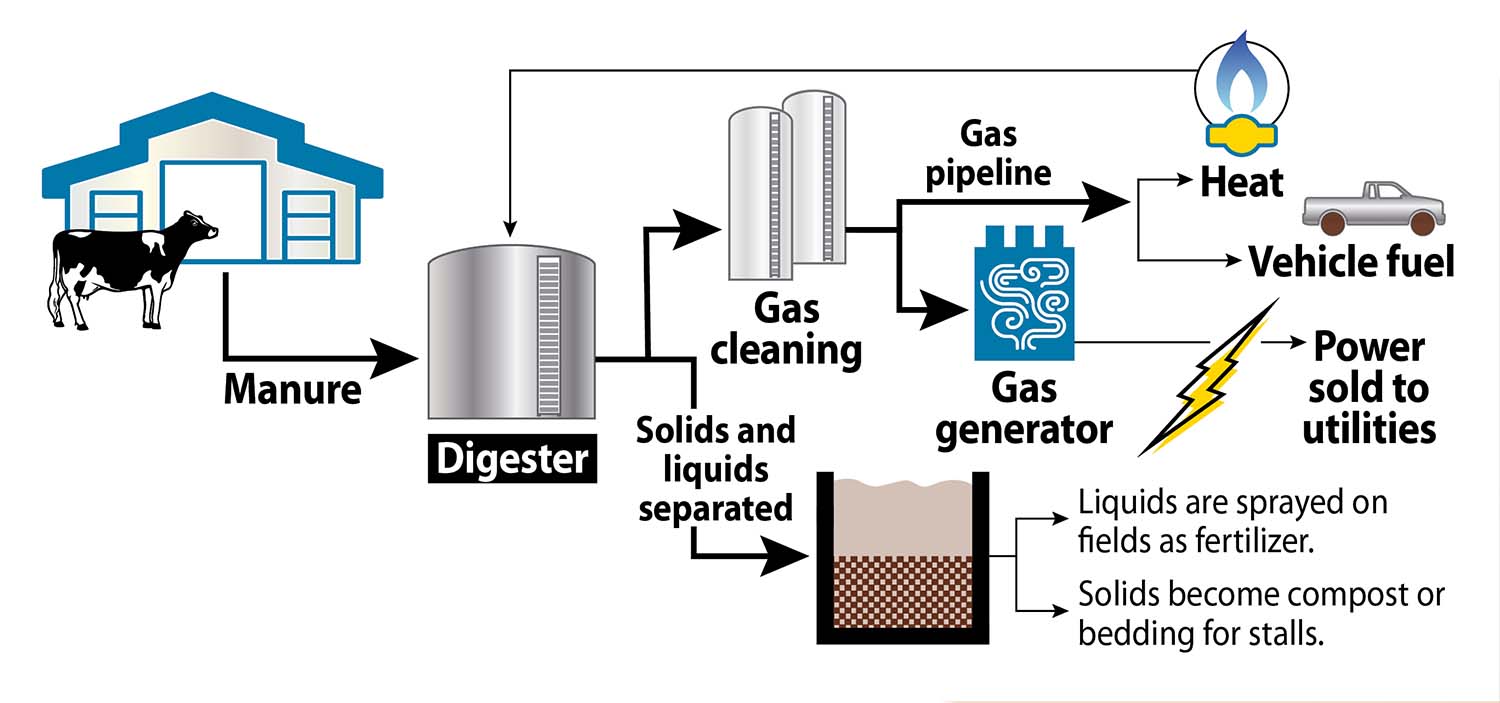

Methane digester working process (Farm Credit)

View open jobs in this Solution

Example Companies

- Anaergia - Develops anaerobic digestion technologies for waste management.

- Bioenergy DevCo - Designs, engineers, and constructs anaerobic digestion facilities.

- Vanguard Renewables - Develops farm-based anaerobic digestion projects.

- Weltec Biopower - Provides biogas and biomethane plant solutions.

- Bright Biomethane - Specializes in biogas upgrading technologies.

Overview

Methane digesters are promoted as tools for reducing greenhouse gas emissions by capturing methane from organic waste and converting it into usable energy. Organizations like the Environmental Protection Agency, the Department of Energy, and the National Renewable Energy Laboratory have been involved in researching and promoting this technology.

Progress Made

Advancements in methane digester technology include:

- High-temperature anaerobic digesters for improved efficiency.

- Enzyme development for enhanced methane breakdown and capture.

- Contributions from companies like GE, Siemens, and Hitachi in technology improvement.

However, it's important to note that while some success stories claim up to 95% reduction in emissions, these figures may not be representative of all implementations and require further verification.

Solutions by Sector

Agriculture

- Farm-Based Digesters: Converting animal waste into biogas.

- Crop Residue Digesters: Utilizing agricultural waste for energy production.

- Co-Digestion Systems: Combining multiple organic waste streams for increased efficiency.

Case Studies:

- Fair Oaks Farms, USA: Large-scale dairy farm using digesters to power operations (Fair Oaks Farms).

- Nature Energy, Denmark: Network of centralized biogas plants processing agricultural waste (Nature Energy).

- Vanguard Renewables, USA: Farm-based anaerobic digestion projects (Vanguard Renewables).

Wastewater Treatment

- Municipal Wastewater Digesters: Capturing biogas from sewage treatment.

- Industrial Wastewater Systems: Managing organic waste from food and beverage industries.

- Sludge-to-Energy Plants: Converting sewage sludge into renewable energy.

Case Studies:

- East Bay Municipal Utility District, USA: Wastewater treatment plant generating more energy than it uses (EBMUD).

- Thames Water, UK: Sewage works producing renewable energy from waste (Thames Water).

- Suez Water Technologies, Global: Anaerobic digestion solutions for wastewater treatment (Suez).

Solid Waste Management

- Landfill Gas Recovery: Capturing methane from decomposing waste.

- Food Waste Digesters: Processing organic waste from households and businesses.

- Integrated Waste Management Facilities: Combining various waste treatment technologies.

Case Studies:

- Waste Management, USA: Landfill gas-to-energy projects across multiple sites (Waste Management).

- ReFood, UK: Network of anaerobic digestion plants processing food waste (ReFood).

- ZeroWaste Energy, USA: Developing advanced anaerobic digestion facilities for municipal solid waste (ZeroWaste Energy).

Lessons Learned

- Community Involvement: Educating and engaging communities is crucial for successful implementation.

- Local Context: Understanding climate, soil, and water conditions is vital for optimal performance.

- Economic Challenges: High costs remain a significant barrier to large-scale adoption.

- Ongoing Research: Continuous R&D is essential for improving technology efficiency and effectiveness.

Challenges Ahead

-

High Costs: The economic viability of methane digesters remains a significant challenge. According to a study by the University of Wisconsin-Madison, many farm-based digesters struggle to be profitable without substantial subsidies or high electricity prices.

-

Infrastructure Limitations: Lack of necessary infrastructure, particularly in rural areas, hinders widespread adoption.

-

Community Opposition: Some communities have raised concerns about odor, increased truck traffic, and potential environmental risks associated with large-scale digesters.

-

Technical Complexity: Operating and maintaining digesters requires specialized knowledge, which can be a barrier for smaller operations.

-

Feedstock Availability: Consistent supply of suitable organic waste can be challenging in some regions.

Best Path Forward

-

Policy Support: Implement supportive policies and incentives to improve the economic viability of methane digesters.

-

Research and Development: Continue investing in R&D to enhance efficiency, reduce costs, and address technical challenges.

-

Education and Outreach: Increase public awareness about the benefits and limitations of methane digesters.

-

Integrated Approach: Promote methane digesters as part of a broader waste management and renewable energy strategy.

-

Collaborative Projects: Encourage partnerships between farms, municipalities, and industries to achieve economies of scale.

While methane digesters show promise in reducing greenhouse gas emissions, it's important to critically assess their overall impact and economic feasibility in different contexts. Future development should focus on addressing the identified challenges and improving the technology's efficiency and cost-effectiveness.

Image credit: Farm Credit