Waste to Energy

Waste-to-Energy (WtE) is a process that converts waste materials into usable forms of energy such as heat, fuels, or electricity. This technology plays a crucial role in reducing greenhouse gas emissions from landfills while simultaneously generating renewable energy.

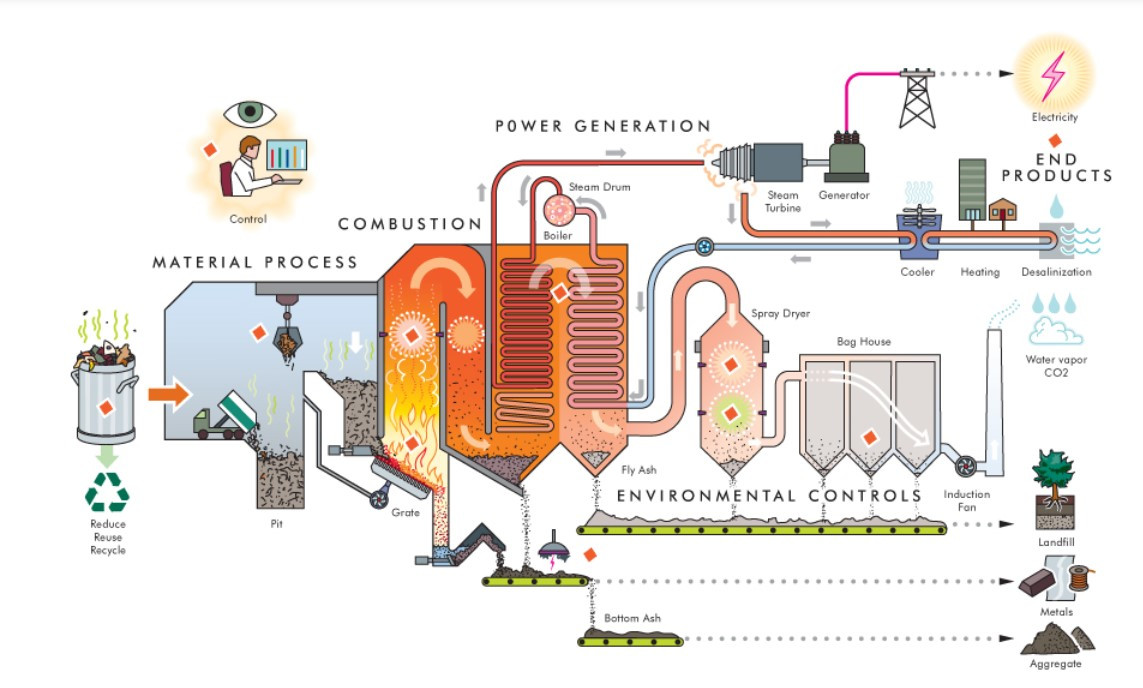

Waste-to-Energy Process (Clean Energy Wire)

View open jobs in this Solution

Example Companies

- Covanta - Operates waste-to-energy facilities globally, converting municipal solid waste into energy.

- Hitachi Zosen Inova - Provides turnkey solutions for waste incineration and energy recovery.

- Enerkem - Specializes in advanced biofuels and chemicals production from waste materials.

- Anaergia - Focuses on integrated solutions for converting organic waste into biogas and renewable energy.

- Advanced Plasma Power - Develops and deploys advanced gasification technology for waste-to-energy conversion.

Overview

Waste-to-Energy technology has made significant strides in combating climate change by efficiently converting waste into usable energy, thereby reducing greenhouse gas emissions from landfills. This process not only addresses waste management issues but also contributes to renewable energy production.

- Carbon Capture Utilization (CCU): Using CO2 from the air instead of fossil fuels to make products - Climate Tech Distillery

Progress Made

Significant advancements have been made in Waste-to-Energy technologies:

- Improved Combustion Technologies: Enhanced efficiency in waste incineration processes.

- Advanced Emissions Control: Development of systems to minimize harmful emissions from WtE facilities.

- Anaerobic Digestion: Refinement of biogas production from organic waste.

- Gasification and Pyrolysis: Advancements in converting waste into syngas and biofuels.

Solutions by Sector

Municipal Solid Waste

- Mass Burn Incineration: Large-scale facilities that burn mixed municipal waste to generate electricity.

- Refuse-Derived Fuel (RDF): Processing waste into a uniform fuel for more efficient combustion.

- Landfill Gas Capture: Collecting and utilizing methane from landfills for energy production.

Case Studies:

- Covanta, USA: Operates numerous waste-to-energy facilities, converting millions of tons of waste into electricity annually (Covanta).

- Amager Bakke / Copenhill, Denmark: A state-of-the-art waste-to-energy plant that also serves as a public recreation area (Amager Resource Center).

- Keppel Seghers Tuas WTE Plant, Singapore: One of the world's largest WtE facilities, processing up to 3,000 tons of waste daily (Keppel Seghers).

Industrial Waste

- Industrial Co-generation: Using industrial waste to generate both heat and electricity.

- Hazardous Waste Incineration: Specialized facilities for safely disposing of and recovering energy from hazardous materials.

- Biomass Gasification: Converting industrial organic waste into syngas for energy production.

Case Studies:

- Enerkem, Canada: Produces biofuels and renewable chemicals from non-recyclable waste (Enerkem).

- Hitachi Zosen Inova, Switzerland: Provides advanced waste incineration technologies for industrial applications (Hitachi Zosen Inova).

- Andritz, Austria: Offers biomass and waste-to-energy solutions for various industries (Andritz).

Agricultural Waste

- Anaerobic Digestion: Converting agricultural waste into biogas for energy production.

- Biomass Direct Combustion: Burning agricultural residues for heat and power generation.

- Thermal Depolymerization: Converting agricultural waste into biofuels.

Case Studies:

- Xergi, Denmark: Specializes in large-scale biogas plants using agricultural waste (Xergi).

- Anaergia, Canada: Develops anaerobic digestion facilities for farm waste (Anaergia).

- Clarke Energy, UK: Provides combined heat and power solutions for agricultural waste (Clarke Energy).

Lessons Learned

- Efficiency Improvements: Continuous technological advancements have significantly increased energy recovery efficiency.

- Emissions Control: Stringent regulations have driven innovations in emissions reduction technologies.

- Waste Hierarchy: WtE is most effective when integrated into a broader waste management strategy that prioritizes reduction and recycling.

- Public Perception: Community engagement and transparency are crucial for successful WtE project implementation.

Challenges Ahead

- High Initial Costs: Significant capital investment required for WtE facility construction.

- Emissions Concerns: Ongoing need to address public concerns about potential pollutants.

- Feedstock Consistency: Ensuring a steady supply of suitable waste for efficient operation.

- Competition with Recycling: Balancing WtE with efforts to increase recycling rates.

Best Path Forward

- Integrated Waste Management: Incorporate WtE as part of a comprehensive waste management strategy.

- Technological Innovation: Continue R&D to improve efficiency and reduce emissions.

- Policy Support: Implement supportive policies and regulations to encourage WtE adoption.

- Public Education: Increase awareness about the benefits and safety of modern WtE technologies.

- Circular Economy Integration: Align WtE practices with circular economy principles to maximize resource recovery.

Prominent supporters include the American Council for an Energy-Efficient Economy, U.S. Environmental Protection Agency, and Department of Energy.

Image credit: Clean Energy Wire